Newsroom

Mechanical parts of rotary kiln

2018-05-09 | Editor:

CHAENG is professional manufacturer supplying large mechanical parts for rotary kiln including rotary kiln girth gear, kiln support roller, kiln tyre, kiln shell segments, kiln thrust roller, large bearing housing and so on. Herein I will introduce main mechanical parts for rotary kin produce by CHAENG.

Rotary kiln girth gear:

1. Girth gear rim is casted in two halves

Rotary kiln girth gear:

| Weight | 10-80T |

| Material | ZG45, ZG42CrMo |

| Application | Ball Mill, Rotary Kiln, Rotary dryer |

| Customizable | Yes, based on user's drawings |

2. Nondestructive testing is performed to ensure zero defects

3. Machining of gear in multiple steps to ensure best finish and accuracy

4. Final quality inspection to ensure CPG quality

1. High strength and good durability

| Weight | 7-42T |

| Material | ZG55, ZG42CrMo |

| Application | Cement, metallurgy, chemical, construction industries |

| Customizable | Yes, based on user's drawings |

1. Bear heavy load, good continuous operation.

Great Wall Steel Casting adopts ZG55, ZG42CrMo etc. so as to guarantee the quality but also has advantages of bearing heavy load and good continuous operation.

2. Simple structure, easy adjustment and repair.

Great Wall Steel Casting adopts rolling bearing wheel and has the characteristics of simple structure, convenient maintenance.

3. Using process of normalizing and tempering, high product hardness.

Great Wall Steel Casting adopts process of normalizing and tempering, surface hardness of encircle is more than 200HB to ensure its great quality.

| Weight | 5-80T |

| Material | ZG45, ZG42CrMo |

| Application | Cement, metallurgy, chemical, construction industries |

| Customizable | Yes, based on user's drawings |

2. Advanced double medium quenching process

3. High quenching hardness

4. Good wear resistance

5. Simple structure and easy to adjust and repair

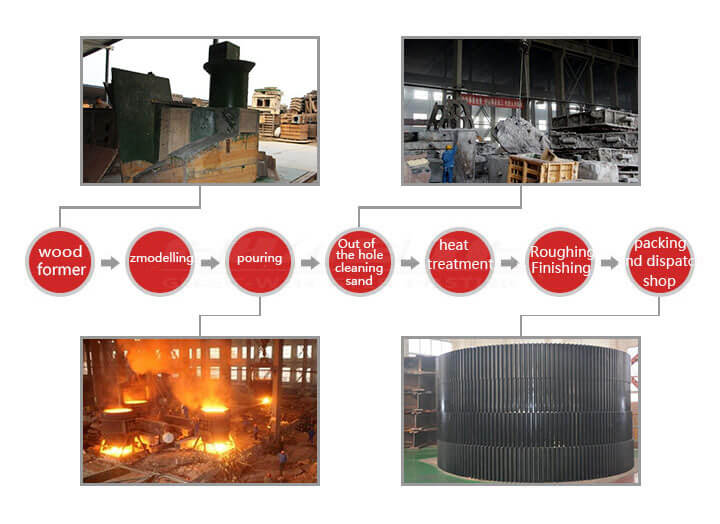

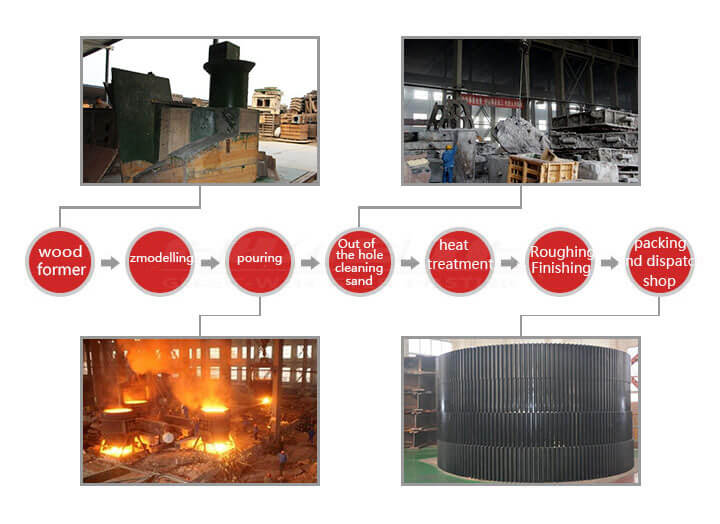

Making process of CHAENG steel castings

1. Wooden pattern Production

2. Molding

3. Pouring

4. First cleaning

5. Heat treatment – grinding (inspection)

6. Rough machining (inspection)-finishing machining (inspection)

7. Packing-delivering

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958