Newsroom

The causes of rotary kiln girth gear vibration

2018-08-31 | Editor:

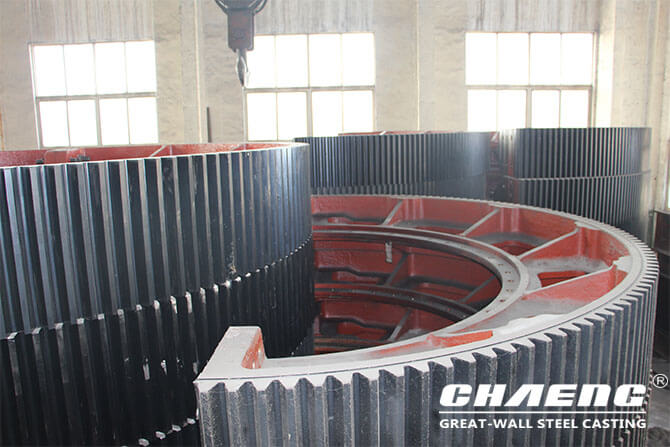

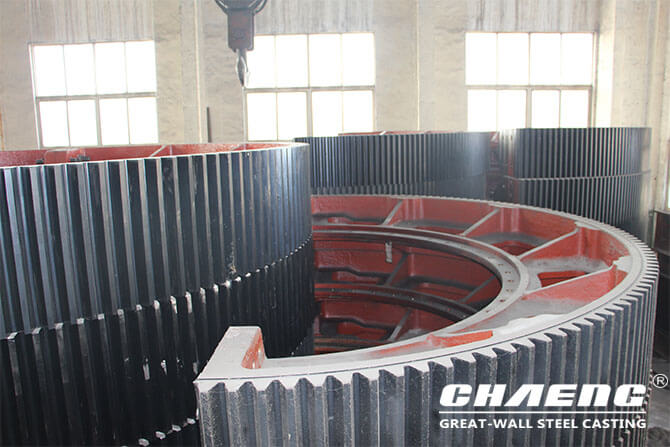

The large girth gear is one of the important accessories of the rotary kiln. Together with the meshed pinion, it is an important part of the rotary kiln rotation system. The main obstacle that may occur in the large girth gear during the operation of the rotary kiln is vibration, which will affect the normal working production of the rotary kiln, so it is important contents of the rotary kiln repair work to make clear the causes of the large girth gear vibration and the corresponding treatment methods.

1. The connectors are worn out. The girth gear is coupled to the kiln body by spring plate pin shafts, and the girth gear itself is manufactured in sections and integrated by the counter screw. If pin shafts and counter screws are worn, the girth gear components are loose, and the local girth gear sinks, which also causes the tooth head clearance to become smaller and results in vibration.

2. The parts on rotary kiln body are worn and the whole kiln sinks. The rotary kiln is a large-load continuous operation equipment. After long-term operation, the components such as the rolling ring, the support roller and the backing pad are worn a lot, and the uneven foundation settlement causes the overall kiln body to fall, so that the tooth top clearance becomes smaller and causes vibration. Sometimes the overall kiln line doesn’t dink, but the drop of the bearing posistion near the girth gear also causes the girth gear vibration.

3. The kiln is bending. The vibration caused by kiln bending occurs mostly in the cold state test, and the hand vibration interval is synchronized with the kiln bending direction. The kiln can be heated up, and the vibration will be eliminated by itself in short time.

4. The girth gear itself is the cause. The top clearance of the transmission gear is generally 0.2-0.25 times the modulus. The rotary kiln girth gear has a large outer diameter, with a radial yaw and other factors, and the top clearance is 0.28 times the modulus plus 0.5-1 mm. At the same time, the radial runout and the axial yaw is no more than 2mm after the large girth gear finishes installation. Most of the girth gear vibration is caused by excessive runout value or yaw value, too-small top tooth clearance, and sharp top teeth of gear and pinion.

5. In most rotary kilns, equilateral triangle is formed between the big gear ring and the center of two small gears in the design ideal meshing state, but the angle has changed after a long time running.

If you need to purchase high quality girth gear, contact CHAENG! We are professional in producing large steel castings with a single weight of more than 1 ton, welcome customers from the world to consult us online!

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:To improve the vertical slag mill efficiency by stabilizing the material bed

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958