Newsroom

To improve the vertical slag mill efficiency by stabilizing the material bed

2018-08-30 | Editor:

The vertical slag mill plays a major role in the treatment of slag in the iron and steel industry. Because of its high fineness, energy saving, environmental protection and stable operation, the vertical slag mill is favored by major enterprises. As customers' demand for slag powder increases, new ideas have also been made in processing slag equipment. For example, whether to improve the efficiency of the mill by stabilizing and strengthening a certain part has become a topic of concern to customers.

In the vertical slag mill, maintaining the stable material bed is the basis of the vertical mill grinding, and it is also the key to the normal operation of the mill. Therefore, we can start from the perspective of stabilizing the bed to improve the efficiency of the mill.

So how to stabilize the bed?

Stable material bed is the guarantee of normal production and standard material grinding of vertical mill. The relationship between material bed thickness and mill output should be found out in the debugging stage of equipment. The thickness of the material layer is closely related to the fineness and output of the finished product. The grinding efficiency of the material layer is reduced when it is too thick, and the vibration will be caused when the material layer is too thin. If the pressure of vertical mill grinding roller increased, the vertical mill will produce more fine powder, the material layer will become thin; if the roller pressure reduced, the materials on grinding table become coarse, the corresponding returned materials become more, and the material layer thickens. So the thickness of the material layer can be adjusted through adjusting the roller pressure.

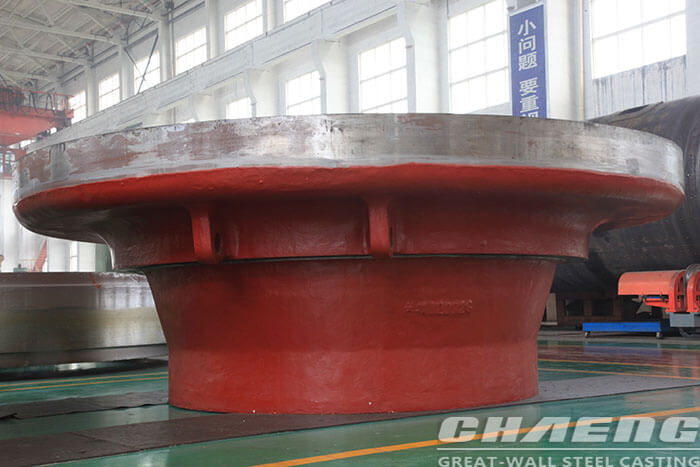

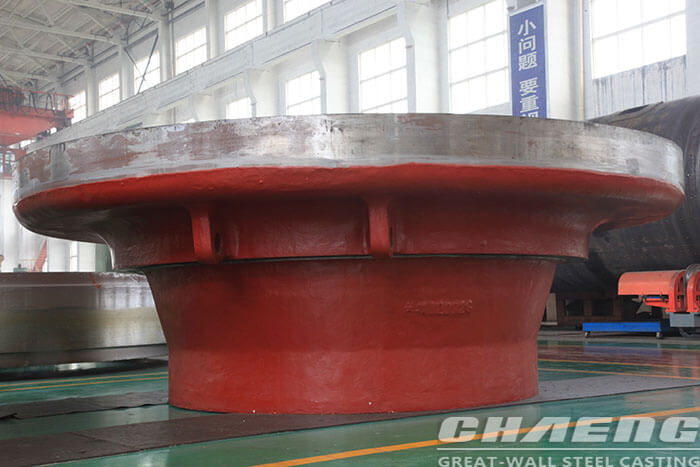

At the same time, the thickness of the material layer can be adjusted by adjusting the height of the retaining ring. The retaining ring is the key component of the vertical mill. Its function is to maintain the material layer on the grinding table. The wear degree of the retaining ring affects the stable operation of the vertical mill. In addition, the wind speed in the vertical mill can also play a role in stabilizing the bed. If the wind speed in the mill is increased, the internal circulation is increased, and then the material layer will be thickened; if the wind speed is reduced, the internal circulation is reduced, and the material layer is thinned. Under normal circumstances, the normal bed thickness is 50-55mm.

To comprehensively understand the functions of the vertical mill components, and improve the efficiency of the slag vertical mill through a safe and effective way, can not only extend the life of the mil, but also improve the economic efficiency.

CAHENG can supply high quality grinding unit for vertical roller mill including rocker arm, grinding roller, grinding table. Welcome to consult us when you are in need!

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958