Newsroom

How to maintain the ring gear of ball mill

2018-05-31 | Editor:

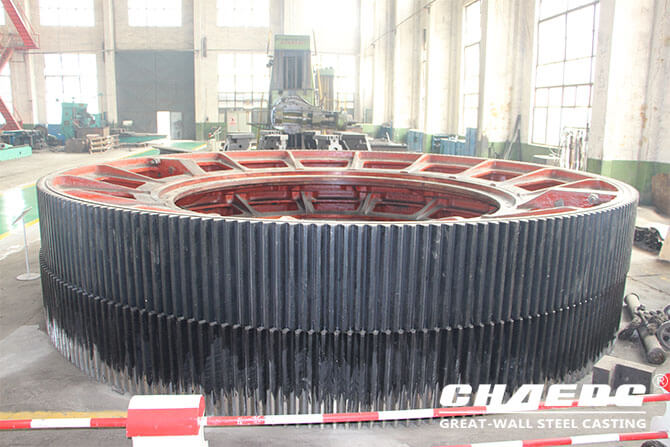

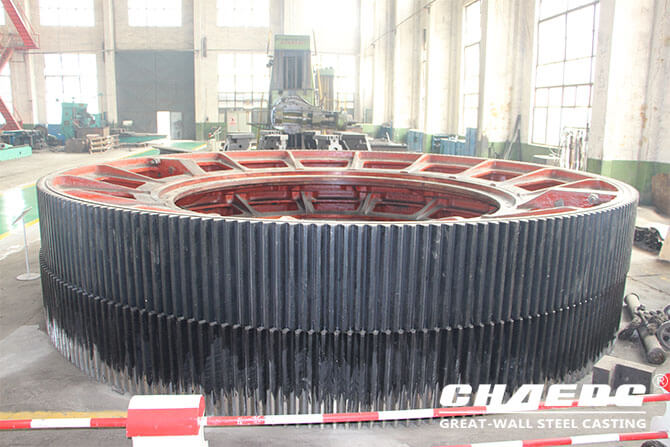

The ball mill ring gear is the most important part to ensure the running of the ball mill, and it is also the one that suffers the most serious wear and tear. Therefore, it is necessary to maintain the large gear carefully.

Then how to maintain the ball mill large gear?

Then how to maintain the ball mill large gear?

Firstly, pay attention to the lubrication of the ball mill gear. The effect of lubrication is to reduce friction, because the wear between the gears in operation is very obvious, add a certain amount of oil can achieve significant results.

Secondly, pay attention to the regular maintenance. Make a check every week, to avoid the whole big gear becoming the elimination part because of excessive wear and tear.

Thirdly, when there is an operating accident, it is advised to stop the ball mill gear. If the condition of missing teeth occurs, carry out timely maintenance or replacement, to avoid the overall ball mill system can not operate normally.

For the ball mill, the maintenance of the ball mill gear is one of the most important measures to ensure the normal operation of the equipment, reduce gear wear, and improve operating efficiency.

If you need to replace your ball mill girth gear, contact CHAENG! CHAENG can manufacture steel casting girth gear according to drawings and demands.

Making process & material of CHAENG girth gear

CHAENG uses high-strength steel materials ZG45, ZG42CrMo to produce girth gear, and optimizes the structure of girth gear according the drive characteristics of rotary kiln and ball mill, to ensure the long-term stability of the girth gear.

Before casting, CHAENG numerically simulates the casting process by means of CAE software to analyze the molding process, predict and optimize the product quality.

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design.

Strictly according to the process procedures to produce high-quality girth gear: wood mold - modelling - pouring - heat preservation - out of the pit, sand cleaning - heat treatment - roughing, finishing - packing and delivery.

We use advanced detection equipment for non-destructive testing to ensure the quality. CHAENG steel castings can meet level-two flaw detection standards.

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958