Newsroom

CHAENG slag ladle types for foundry

2018-06-01 | Editor:

Slag ladle is important container holding high temperature liquid metal slag, mainly tank, lug, supporting foot, tilting arm etc. With richly experience, CHAENG has the capability to offer slag ladle in nearly every shape and style for a variety of mounting systems and transport methods, according to customers’ drawings, utilized in BOFs, AODs, Electric Arc and Blast Furnaces, and so on, suited for a number of processes, such as lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications.

CHAENG is equipped with two sets of 60-ton basic electric arc furnaces, can supply slag ladles with piece weight range from 1 ton to 150 tons, with steel materials of ZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on.

Cases of CHAENG slag ladles:

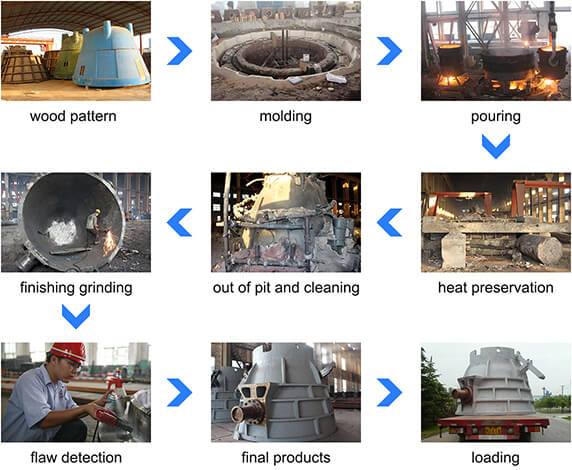

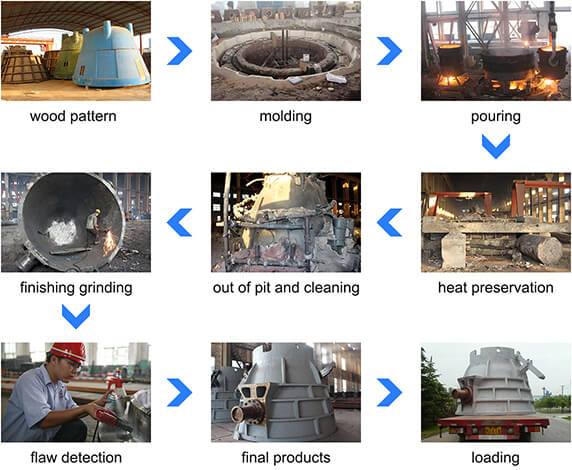

Making process of CHAENG slag ladles:

The first step: simulation, modeling

Before casting, numerically simulate the casting process by CAE software to analyze the molding process, predict and optimize the product quality.

The second step: pouring, heat treatment

Perform the spectral analysis on the sample of hot metal. After qualified, start pouring according to the principle of "low temperature and quick casting", and the pouring time and temperature shall be recorded.

The third step: finishing, flaw detection

CHAENG uses advanced detection equipment for non-destructive testing to ensure the internal quality of slag pot. CHAENG steel castings can meet level-two flaw detection standards.

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958