Newsroom

CHAENG GRM vertical roller mill separator

2018-05-30 | Editor:

CHAENG has the largest steel casting base in the north of Henan Province, is able to manufacture main spare parts for vertical mill independently, which not only shorten the time of delivery, but also make the quality of the spare parts of vertical mill such as slag vertical mill, cement mill, and raw material vertical mill effectively guaranteed.

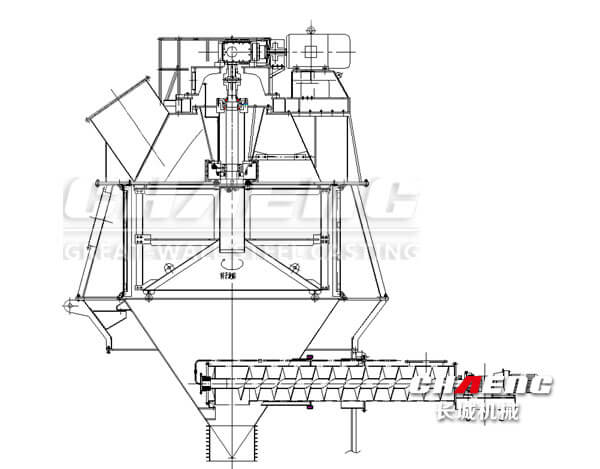

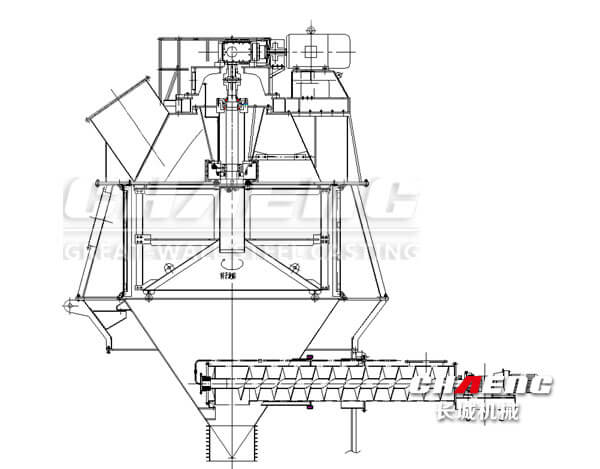

Cage rotor of vertical mill separator

CHAENG dynamic high-efficiency vertical mill separator, also known as classifier, is installed on the upper part of the vertical mill and is connected with the middle shell. The separator consists of shell, cage rotor, air guide vane and transmission device. Its internal structure is reasonable, the efficiency of powder selection is high, and the energy-saving effect is obvious.

Advantages of CHAENG vertical mill separator:

1. Advanced classifying principle, improved dispersion degree. The classification areas are designed based on the classification principle of O-SEPA (that is, the eddy current classification zone composed of guide vane and cage rotor), and additional dispersion and pre-classification areas will be separated with dispersion and separation (separation) areas, to greatly improve the dispersion of the material, reduce the load of the main classification area, and release the mutual interference of the coarse and fine particles of the material.

Cage rotor of vertical mill separator

2. Fineness Adjustment. The fineness of a simple finished product depends on the rotor speed. To increase the speed of the rotor, the fineness of the milled material is finer; on the contrary, if the speed of the rotor is reduced, the particles of the material will become thicker.

3. Significant energy-saving effect. CHAENG vertical mill separator adopts a streamlined design, which significantly reduces the resistance of the system. The powder circulation is circulated internally. The collection of fine powder only requires the use of a high-efficiency, low-resistance cyclone, and no large-scale air box pulse dust collector is required. In this way, not only the system power consumption is reduced, but also the investment costs and maintenance costs are reduced, and the advantages of energy saving and consumption reduction are very significant.

4. Improve the quality of finished products, and avoid over-grinding. Because of the high efficiency and high precision of the powder separator, the phenomenon of over-grinding of the material is reduced, the particle size distribution of the finished product is narrow, and the gradation composition is reasonable.

Typical case:

Shanghai Baosteel slag vertical mill separator installation picture

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Support roller and bearing structure of cement rotary kiln

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958