Newsroom

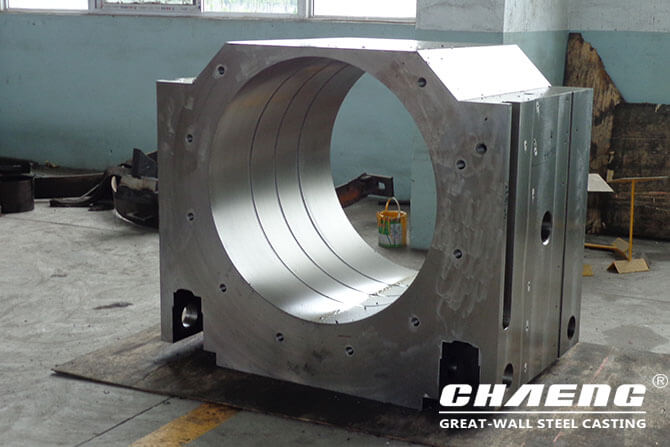

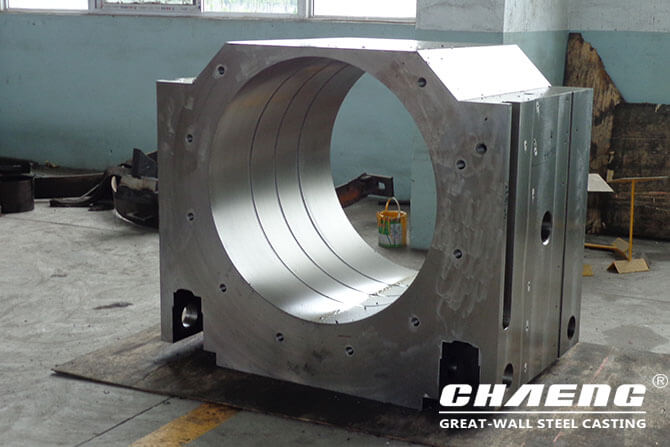

Work roll chock of rolling mill - choose manufacturer CHAENG

2018-10-22 | Editor:

The rolling mill work roll chock made by CHAENG (Great Wall Steel Casting) is mainly made of cast steel. After heat treatment, it has good wear resistance and high strength. Since the work roll chock is the main force-bearing member in the whole equipment operation, it also requires a certain shock absorption performance. So when CHAENG manufactures the chock, each step is complicated and very strict from casting materials to heat treatment.

Making process of CHAENG work roll chock:

1. Software simulation

Using CAE software to digitally simulate the casting process, predict product defects and other issues, so as to develop technical solutions in advance and avoid casting defects, which is a new realm of large-scale sand casting technology.

2. Wood mold modeling

Control the mold and molding process with instruments such as infrared range finder, coordinate measuring machine and endoscope.

3. Molten steel casting

The company has two 60-ton alkaline arc furnaces, and also introduced German OBLF GS1000 vacuum direct reading spectrometer, carbon-sulfur high-speed analyzer, and microcomputer three-element high-speed analyzer to carry out refined inspection of molten steel components.

4. Out of the pit, cleaning the sand

The latest introduction of a large-scale trolley-type automatic shot blasting machine can clean the castings faster and more efficiently.

5. Heat treatment

Our company has 4 large-scale natural gas heat treatment furnaces, the largest of which is 6*6*16.5 meters, which can meet the heat treatment requirements of different sizes of products.

6. Machining

A machining (group) center, 8 sets of various submerged arc welding machines; 6 sets of various quenching and electric furnaces; 22 sets of lifting equipment, leading equipment, high degree of intelligence, maximum lifting capacity 200T, meeting the Great Wall casting The need for steel to produce finished products.

The work roll chock, like the bearing, must be regularly maintained to detect problems early, so as to improve productivity and service life. CHAENG can produce large work roll chock according to your drawings, contact us!

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Congratulations! CHAENG slag pots passed the acceptance of Austrian customers

Next:Spare parts of hydraulic presses for ceramic industry - types and cases made by CHAENG

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958