Newsroom

Customized slag pot manufacturer in China - CHAENG

2018-03-09 | Editor:

Slag pot is also called casting ladle, slag bucket, or slag ladle. It is important container holding high temperature liquid steel slag in the process of steel making, the main structure contain parts of tank, lug, supporting foot, tilting arm etc.

CHAENG has the capability to cast slag pots in nearly every shape and style for a variety of mounting systems and methods of transport.

CHAENG engineers adopt suitable material ZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on, customize and optimize the casting technology according to actual operating conditions. So CHAENG slag pots have: excellent high temperature mechanical properties, good thermal cracking resistance, stable manufacturing process and so on.

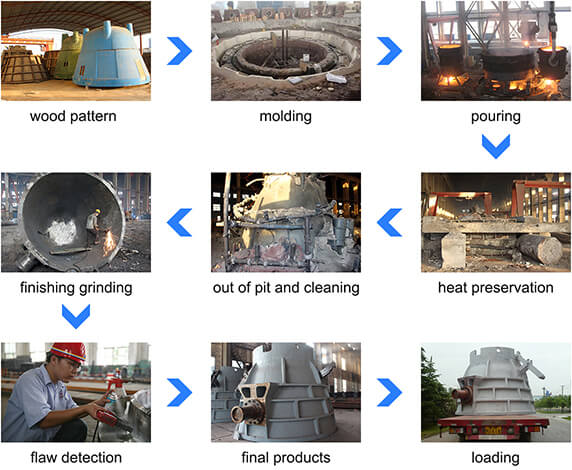

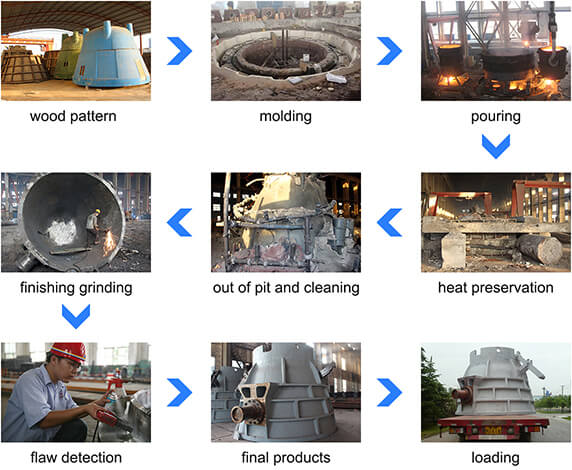

Process of CHAENG slag pot:

Process of CHAENG slag pot:

Except the supply of the forgings for trunnions and the engineering of the pattern, all further operations are carried-out at the in-house foundry plant.

• Moulding

Sand moulding.

• Trunnions

The trunnions - when any - are preferably cast-in: they are as a rule manufactured from the steel material S355 J2G3 to DIN EN 10250-2.

• Melting

The melting is carried out in the oxygen steel plant; the ladle capacity allows a continuous bottom pouring process the speed of which is permanently controlled. The metal analysis is checked by using a computer linked spectrograph.

• Heat treatment

- Heating to a temperature above AR3, austenitising at about 915°C and controlled cooling in furnace

- Intermediate holding at 600°C - 630°C and completion of cooling in furnace down to 300°C

• Fettling and dressing

The inner surface is processed fit-for-purpose so that the surface discontinuities - which might cause some sticking of the slag - are extensively removed. Additionally, the castings are descaled by shotblasting and the outside is additionally coated for transportation.

Advantages of CHAENG slag pot:

1. Mittal orders over 100 CHAENG slag pots annually

1. Mittal orders over 100 CHAENG slag pots annually

Large steel plant of the world - Mittal Group purchases CHAENG slag pot very year since 2008. The order amount has been over 100 pieces / year by now. At present, CHENG has become a long-term strategic partner of Mittal Steel Group.

2. Longer service life, 6000 usage times

The slag pots in the market can be used 450-600 times generally, while CHAENG slag pot can ensure *** of usage frequency; and the first maintenance time is 2-3 months later than peers. The long service life of CHAENG slag pot greatly reduce the maintenance cost of users.

3. Advanced Level-2 Flaw Detection Standard

CHAENG uses advanced detection equipment to perform nondestructive testing on each slag pot, to ensure the internal quality of slag pot. The key parts can reach level-2 testing standards of GB7233-2007, and CHAENG can customize the process according to the customer's specific testing standards.

4. Exported to 50 countries and areas

CHAENG customizes slag pots according to customer drawings, obtaining market reputation with high-precision technology. CHAENG slag pots have been successfully exported to the United States, Mexico, Brazil, India, South Korea, Japan, Russia, more than 50 countries and regions.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Rolling mill stand housing - featured product of CHAENG

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958