Newsroom

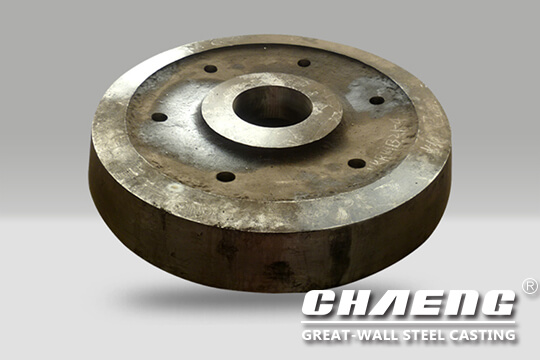

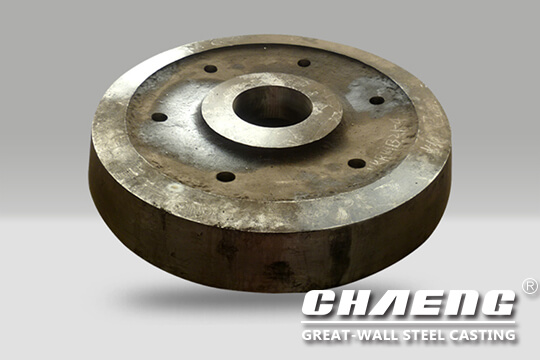

Use of large rotary kiln accessory thrust roller

2019-06-04 | Editor:

The role of the rotary kiln thrust roller:

The rotary kiln shell is rotated by the inclination of 3 to 5 percent and then supported by the support roller. When the rotary kiln is rotated, the shell should be moved up and down. This turbulence is also within a certain range . If you want to observe in time or control the kiln's turmoil, you can hold the thrust roller on both sides of one of the tyre. The thrust roller can display the operation of the shell in the support wheel, and it will also limit or control the movement of the shell, so its role is still relatively large.

The thrust roller can also be divided into three types: the non-powerful thrust roller, the strenuous thrust roller, and the hydraulic thrust roller. Each of these three thrust roller has its own unique characteristics. The large rotary kiln fittings generally use a hydraulic thrust roller device that can be supported by two trunnions, so that the support trunnion is fixed to the base. The trunnion can slide parallel along the support trunnion under the push of the piston rod.

After the rotary kiln is equipped with the thrust roller, the support roller and the kiln tyre can be installed in parallel, and the kiln body is also gradually moved downward under the action of elasticity, and when a certain position is reached, the hydraulic oil pump is started. The oil produced by the oil pump can push the thrust roller and the kiln body upwards, and then push the limit switch to the specified position. At this time, the oil pump will stop working and will move downward according to the elastic sliding action. If the speed of moving is too fast, there will be nicks on the tyre and on the gears.

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958