Newsroom

CHAENG slag pots for steel plant, serviced large steel companies in Germany, USA, Finland, South Africa

2018-05-25 | Editor:

With richly experience and advanced casting equipment, CHAENG has the capability to offer slag pots (ladles) in nearly every shape and style for a variety of mounting systems and transport methods, according to customers’ drawings, utilized in BOFs, AODs, Electric Arc and Blast Furnaces, and so on, suited for a number of processes, such as lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications.

Slag pots are the star product of CHAENG, and more than 95% are exported overseas. Since the signing of the first slag pot ordering contract in July 2008, CHAENG has manufactured 50 types and 300 pieces of finished slag pots which were sold to the world, such as the United States, Canada, Mexico, Brazil, Germany, Finland, Turkey, India, Korea, Belgium and others.

Reference cases of CHAENG slag pots:

Mittal Steel Group South Africa Branch purchased three slag pots from CHAENG

American steel company ordered more than ten CHAENG slag pots at a time

Mittal Group purchases CHAENG slag pot every year since 2008. The order amount has been over 100 pieces / year by now.

Finland steel company purchased five slag pots from CHAENG, and the Finnish customers said that if there were other steel product demands in the follow-up, CHAENG would be given priority.

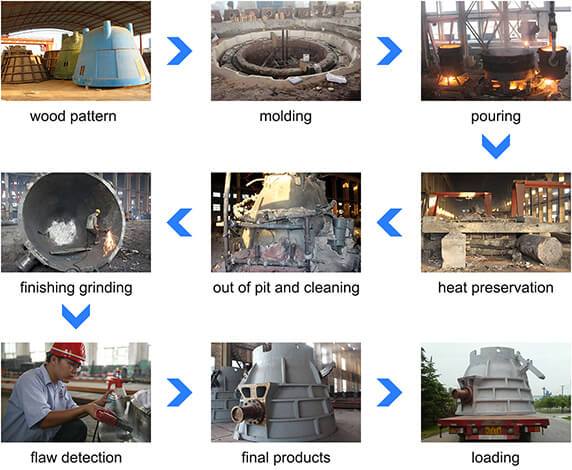

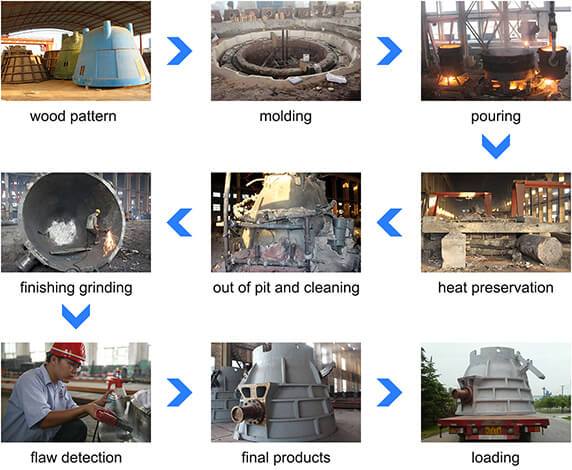

Material and process of CHAENG slag pot:

CHAENG adopts ZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on steel materials to produce slag pots. Before production, CHAENG communicates fully with customers to make specific production plan of slag pot; strictly control every procedure of mold, modelling, casting and testing for the pursuit of 100% quality; regularly train the front-line operatives, to ensure stable production quality of slag pot.

Contact us!

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:Crossbeam, base, frame, column for press machine - steel casting parts

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958