Newsroom

CHAENG slag pot cases and advantages

2018-04-16 | Editor:

CHAENG has the capability to offer slag pots in nearly every shape and type for a variety of mounting systems and transport methods, according to customers’ drawings, utilized in BOFs, AODs, Electric Arc and Blast Furnaces, and so on.

CHAENG uses cast steel materials ZG230-450, ZG270-500, ZG310-570, ZG340-640 and so on to produce high quality slag pots, suited for a number of processes, such as lead, aluminium, iron, steel, chrome, manganese, copper and other smelting applications.

CHAENG uses advanced detection equipment to perform nondestructive testing on each slag pot, to ensure the internal quality of slag pot. The key parts can reach level-2 testing standards of GB7233-2007, and CHAENG can customize the process according to the customer's specific testing standards.

The slag pots in the market can be used 450-600 times generally, while CHAENG slag pot can ensure *** of usage frequency; and the first maintenance time is 2-3 months later than peers. The long service life of CHAENG slag pot greatly reduce the maintenance cost of users.

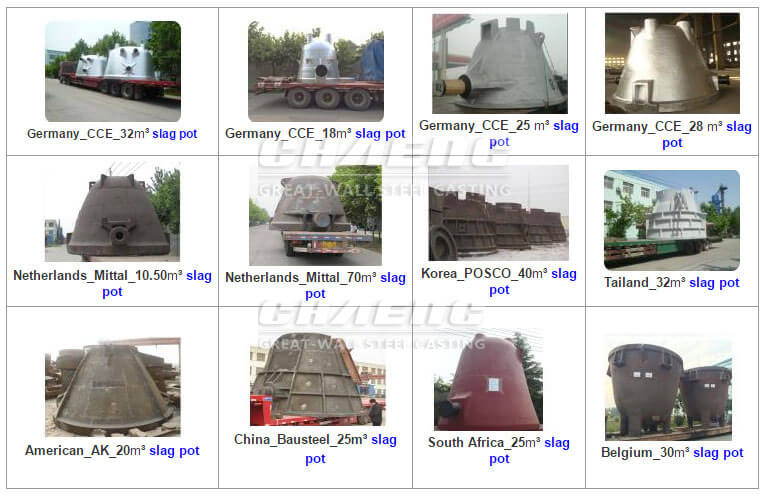

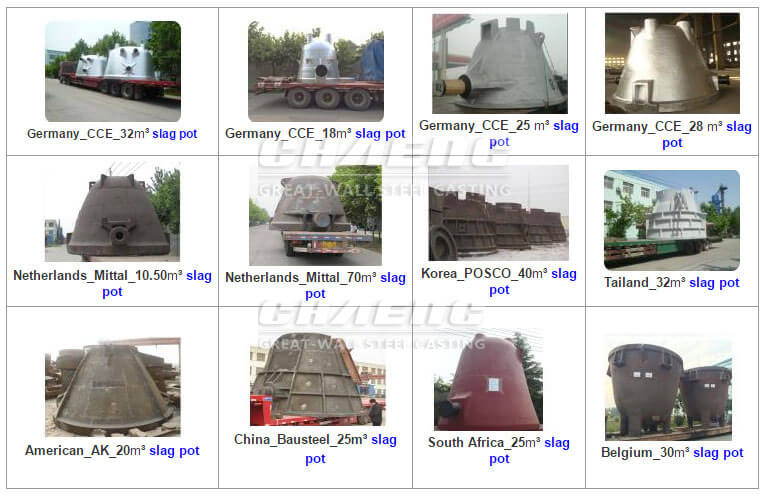

Slag pot cases of CHAENG

Slag pot cases of CHAENG

Contact us if you are interested in our slag pots!

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958