Newsroom

Why CHAENG? - the professional rotary kiln riding ring manufacturer

2020-11-20 | Editor:

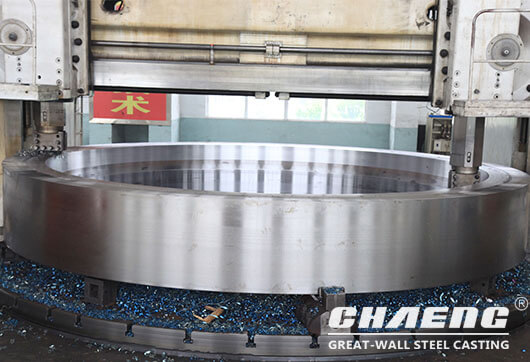

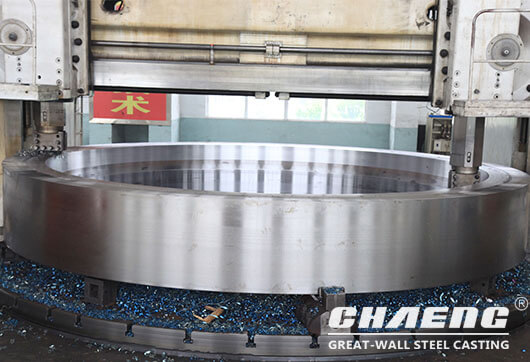

CHAENG's extensive experience and production strength in rotary kiln spare parts have won the trust of our customers. The rotary kiln riding ring (rotary kiln tyre) is the key component that supports the full gravity of the rotary kiln (including kiln bricks and materials). The rotary kiln riding ring made by CHAENG has sufficient strength, durability and rigidity.

How CHAENG to ensure the quality of the rotary kiln riding ring?

How CHAENG to ensure the quality of the rotary kiln riding ring?

1. CHAENG uses ZG45 and ZG42CrMO material, which can guarantee the strength and toughness of rotary kiln tyre, so as to play a better supporting role.

2.Advanced casting equipment

Two sets of 60T basic electric arc furnace, smelting steel with once 140T;7M *12M and 5M*7M 2sets natural gas heat treatment furnace;22 sets of hoisting equipment, Max. lifting capacity is 150 tons; Maximum elevating capacity is 150 tons; The company is equipped with gas stations, oxygen station, carbon dioxide station, air compression station, etc; It adopts the sodium silicate sand molding process, and adopts the CAE casting simulation software to shorten the trial-produce period and improve the quality of products. 3. CHAENG has a professional processing team, a meticulous production plan, high-quality raw material purchase channels, a complete logistics system. Able to complete the customer's requirements within the shortest delivery time.

3. CHAENG has a professional processing team, a meticulous production plan, high-quality raw material purchase channels, a complete logistics system. Able to complete the customer's requirements within the shortest delivery time.

1. CHAENG uses ZG45 and ZG42CrMO material, which can guarantee the strength and toughness of rotary kiln tyre, so as to play a better supporting role.

2.Advanced casting equipment

Two sets of 60T basic electric arc furnace, smelting steel with once 140T;7M *12M and 5M*7M 2sets natural gas heat treatment furnace;22 sets of hoisting equipment, Max. lifting capacity is 150 tons; Maximum elevating capacity is 150 tons; The company is equipped with gas stations, oxygen station, carbon dioxide station, air compression station, etc; It adopts the sodium silicate sand molding process, and adopts the CAE casting simulation software to shorten the trial-produce period and improve the quality of products.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:To know CHAENG, a professional slag pot manufacturer in China

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958