Newsroom

CHAENG introduces girth gear to you

2017-12-04 | Editor:

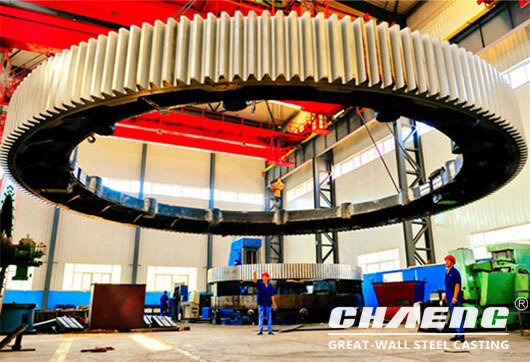

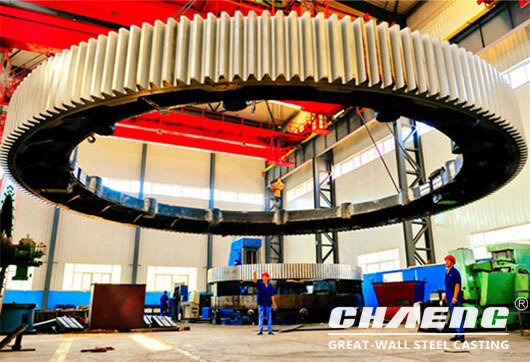

CHAENG, as a professional steel casting manufacturer in China, has many years’ experience in supplying custom services for large steel castings. Girth gear for ball mill and rotary kiln is the key product of CHAENG, receiving many praises form users.

Advantages of CHAENG girth gear:

1. Special Heat Treatment Technology

CHAENG adopts special heat treatment technology to optimize structure, improve hardness and enhance impact resistance of girth gear.

2. Long Service Life

CHAENG adopts high strength steel to produce girth gear. Firstly characteristics optimization of rotary kiln is done to guarantee its stability during long time operation, also to prolong its working life.

3. Factory Price Custom & Quick Delivery

CHAENG has strong steel casting production capability, and it can provide girth gear in large quantity with short period.

Process of CHAENG girth gear

Base on the requirements of customers, CHAENG selects appropriate wooden mold for modeling design, and uses CAE software to simulate the casting process. Strictly according to the process procedures to produce high-quality girth gear: wood mold - modelling - pouring - heat preservation - out of the pit, sand cleaning - heat treatment - roughing, finishing - packing and delivery.

CHAENG can manufacture 2-14m girth gear according to users’ drawings. Welcome to consult for more details!

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958