Newsroom

Which is better, the casting girth gear or forging girth gear?

2018-06-04 | Editor:

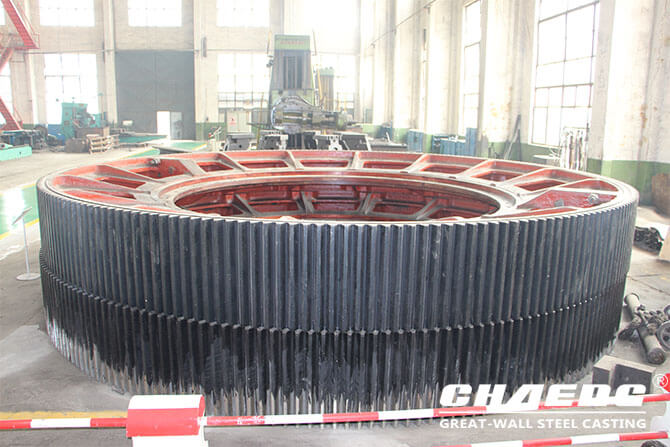

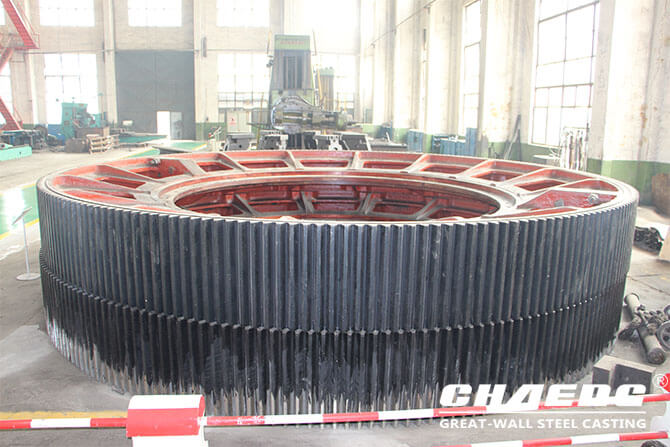

CHAENG (Great Wall Steel Casting) is a professional ball mill and rotary kiln girth gear manufacturer in China, providing girth gear processing services for many leading enterprises both at home and abroad. In the minds of many customers, there is such a question: Is the casting girth gear better, or the forging girth gear?

Girth gear is the transmission component and plays a key role in the operation of the entire machine. If the girth gear wears out, the machine needs to be stopped for maintenance. In addition, girth gears are also wearing parts, frequent replacement of gears will affect the production schedule, and also greatly increase the maintenance cost. Therefore, when selecting gears, we must pay attention to the selection of gear materials and processes.

Under normal circumstances, in order to have a long life, girth gears are required to have strong wear-resistance, shock-resistance and high strength. Regarding the processing technology, CHAENG believes that the pinion has a high rotational speed and a relatively short service life, so the forging process is better because the forged parts have a dense texture, and the hardness and wear resistance are better than the steel castings. However, the girth gear has a relatively low rotational speed and it is more appropriate to select the casting process. On the one hand, the casting process can meet the need for long-term rotation of mechanical equipment, on the other hand, it can also save production costs and maintenance costs.

CHAENG, as a professional girth gear processing factory, can provide customers with 2m-8m steel casting girth gears. CHAENG adopts special heat treatment technology to optimize structure, improve the hardness and enhance the impact-resistance of girth gear.

Order online

Fill out your message and submit it . Options with * must be filled in.

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958