Newsroom

The Experience Sharing of Pouring Ring Gear

2016-05-17 | Editor:

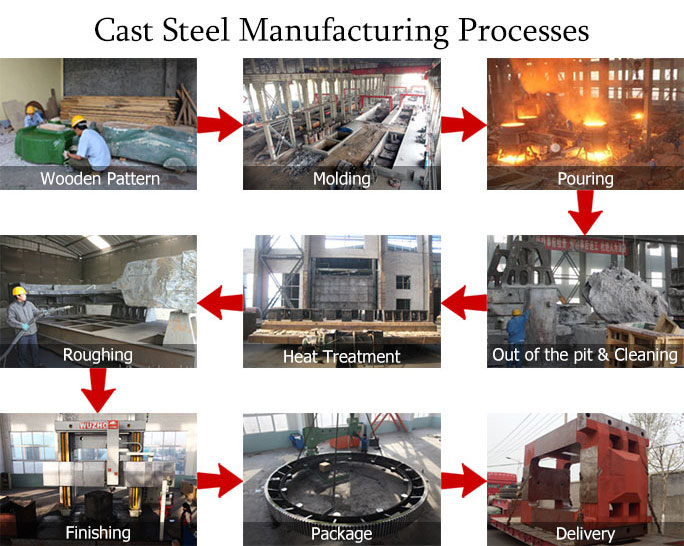

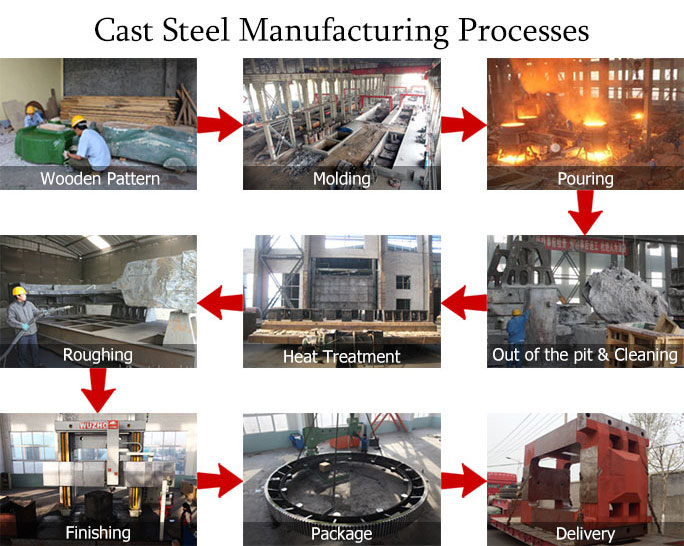

Casting process is a vital part in the entire production process, if the link does not properly handled, the qualified casting ring gear is very difficult, so the ring gear production, we should be strictly in accordance with the requirements to cast link the operation.

First, before pouring enterprises should get prepared to ensure that the subsequent casting operation can proceed smoothly.

Before pouring preparation includes:

A.cleanup site pouring, to ensure the successful completion of the casting process safety;

B.Flexibility repair quality inspection ladle drying and preheating Transport and tilting mechanism and reliable offerings;

C.Understand the type of alloy cast, the casting mold to be estimated by the number and weight of molten metal required to prevent the molten metal is insufficient, the insufficient number of molds in casting phenomenon.

In order to obtain qualified ring gear, and strictly control the pouring temperature, pouring speed, pouring strict compliance procedures is critical.

(1) For the purposes of pouring temperature, pouring temperature great influence on casting quality, it should be based on the type of alloy castings, structures and characteristics of mold pouring determine a reasonable temperature range. Choose a reasonable pouring temperature depends on the type of carbon steel at 1540 ℃ ~ 1580 ℃ (the temperature of the molten steel within the ladle) temperature is generally between pouring.

(2)On the casting speed, in the cavity gas discharge ensure smooth conditions, require simultaneous solidification of the casting may be higher casting speeds required to achieve solidification of the casting, as far as possible the use of lower cast speed.

(3) For the purposes of the requirements of casting operations in accordance with generally required to comply with the following: a pouring large and medium-sized ring gear, pouring molten steel to be standing after 1min ~ 2min killed in the ladle; b pouring until after solidification. complete, should be promptly removing weights and box cards to reduce the casting shrinkage resistance, crack avoid casting defects.

On the current situation of various materials accounting for castings, steel castings in recent years, accounting for about all kinds of material castings 12% of total production, the casting for the development of the whole industry has a great influence, reasonable in the production of ring gear arrange all aspects of improving the quality of the ring gear, in order to achieve promote the development of the entire casting industry.

On the current situation of various materials accounting for castings, steel castings in recent years, accounting for about all kinds of material castings 12% of total production, the casting for the development of the whole industry has a great influence, reasonable in the production of ring gear arrange all aspects of improving the quality of the ring gear, in order to achieve promote the development of the entire casting industry.

First, before pouring enterprises should get prepared to ensure that the subsequent casting operation can proceed smoothly.

Before pouring preparation includes:

A.cleanup site pouring, to ensure the successful completion of the casting process safety;

B.Flexibility repair quality inspection ladle drying and preheating Transport and tilting mechanism and reliable offerings;

C.Understand the type of alloy cast, the casting mold to be estimated by the number and weight of molten metal required to prevent the molten metal is insufficient, the insufficient number of molds in casting phenomenon.

In order to obtain qualified ring gear, and strictly control the pouring temperature, pouring speed, pouring strict compliance procedures is critical.

(1) For the purposes of pouring temperature, pouring temperature great influence on casting quality, it should be based on the type of alloy castings, structures and characteristics of mold pouring determine a reasonable temperature range. Choose a reasonable pouring temperature depends on the type of carbon steel at 1540 ℃ ~ 1580 ℃ (the temperature of the molten steel within the ladle) temperature is generally between pouring.

(2)On the casting speed, in the cavity gas discharge ensure smooth conditions, require simultaneous solidification of the casting may be higher casting speeds required to achieve solidification of the casting, as far as possible the use of lower cast speed.

(3) For the purposes of the requirements of casting operations in accordance with generally required to comply with the following: a pouring large and medium-sized ring gear, pouring molten steel to be standing after 1min ~ 2min killed in the ladle; b pouring until after solidification. complete, should be promptly removing weights and box cards to reduce the casting shrinkage resistance, crack avoid casting defects.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:How to control defects in steel casting node manufacturing

Next:what material does Great Wall rotary kiln support roller use?

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958