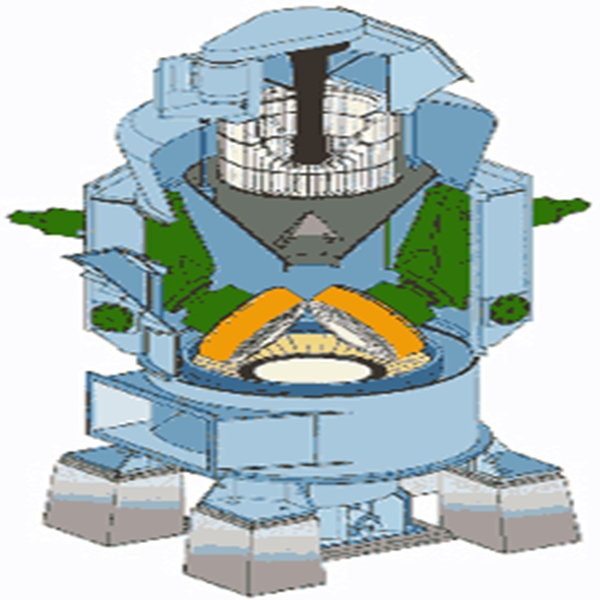

The most important spare parts in a vertical roller mill are the grinding rollers and grinding tables (also called respectively vertical mill tires and rings). Several grinding rollers (two to six according to the size of the vertical roller mill) are placed around the grinding table. A vertical roller mill takes its name after the vertical axis upon which it rotates. The material to be ground is fed into the mill from its top. It falls on the table placed at the bottom of the vertical roller mill.

Due to the centrifugal force generated by the rotation of the main shaft the grinding rollers are pressed closely upon the grinding ring and grind the material fed into the mill (raw, cement or coal for instance) as they roll. The qualified material (the one which has reached the requested size) will leave the mill with the airflow while the unqualified one will be brought back to the grinding chamber for another round of grinding.

Great Wall manufactures vertical mill internals in high wear resistance steels and irons, be they standard mono alloys, bi-metal or composite. Great Wall pioneered the use of composite solutions in vertical mill internals, vertical mill rollers as well as vertical mill tables (or vertical mill tires as well as rings).

Prev:slag vertical roller mill lead the development of slag processing industry

Next:Where is the future development direction of cast steel industry

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958