Newsroom

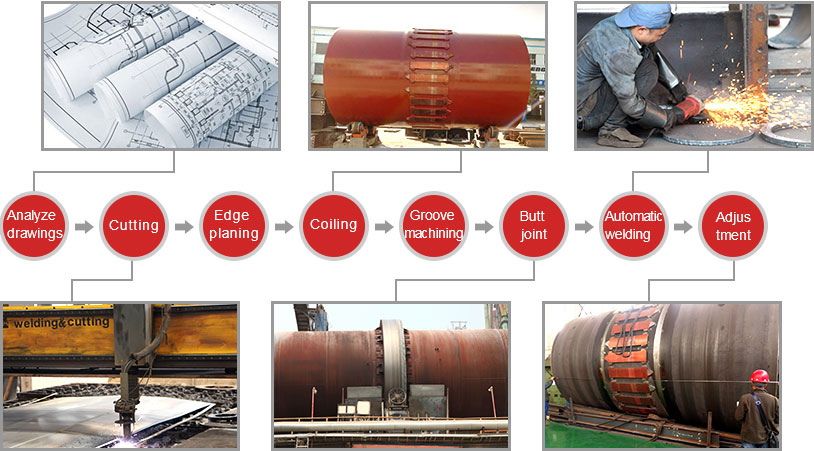

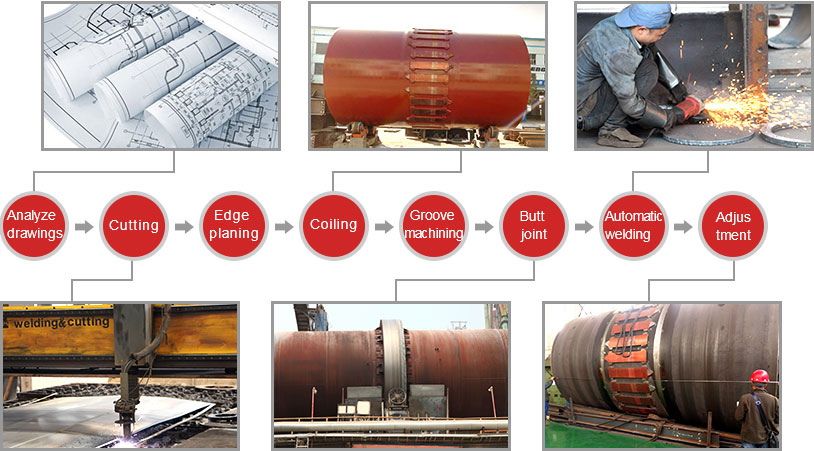

Manufacturing process and maerials of rotary kiln shell

2021-11-02 | Editor:

Rotary kiln can be divided into cement rotary kiln, metallurgical rotary kiln, chemical rotary kiln and lime rotary kiln according to different materials. Regardless of the type of kiln, the kiln shell is a key component of the equipment. Rotary kiln shells are generally made up of Q235 and Q345.

CHAENG has close cooperation with many companies of various industries, supplying them with spare parts with good performance to improve the practical effect of the equipment and extend the service life of the equipment. CHAENG has won the high praise of customers

CHAENG has close cooperation with many companies of various industries, supplying them with spare parts with good performance to improve the practical effect of the equipment and extend the service life of the equipment. CHAENG has won the high praise of customers

Due to transportation reasons, the rotary kiln is composed of shell segments. Because the outer circle of the kiln cylinder is not processed, the perpendicularity of the end face to the center of rotation cannot be directly measured. In the process design, the perpendicularity of the end face is converted into parallelism and the coincidence of the axes at both ends according to the structure of the cylinder.

CHAENG designs specific manufacturing and welding processes of single-segment shells according to the detailed requirements of the drawings. After the assembly and welding of the cylinder, perform the post-weld treatment, including non-destructive testing, post-weld heat treatment, and pressure resistance test to ensure the high quality of the kiln shell.

Order online

Fill out your message and submit it . Options with * must be filled in.

Prev:What is CHAENG rotary kiln support roller material?

Next:CHAENG participated in the Fifth National Foundry Industry Summit Forum

PRODUCTS

CONTACT

- Tel: +8613223717221

- Whatsapp: +8613223717221

- E-mail: casting@chaeng.co

- Skype : GreatWall1958